Concept-X

Innovative solution at future construction sites.

HD CONSTRUCTION EQUIPMENT does not simply adopt digital technology. It seeks to revolutionize the construction machinery industry and create sustainable customer value through the digital transformation of business. To achieve this, HD CONSTRUCTION EQUIPMENT implements the “Concept-X” project, which spearheads the implementation of the future construction site by converging and integrating technologies related to ICT (Information and Communications Technology) and AI (Artificial Intelligence).

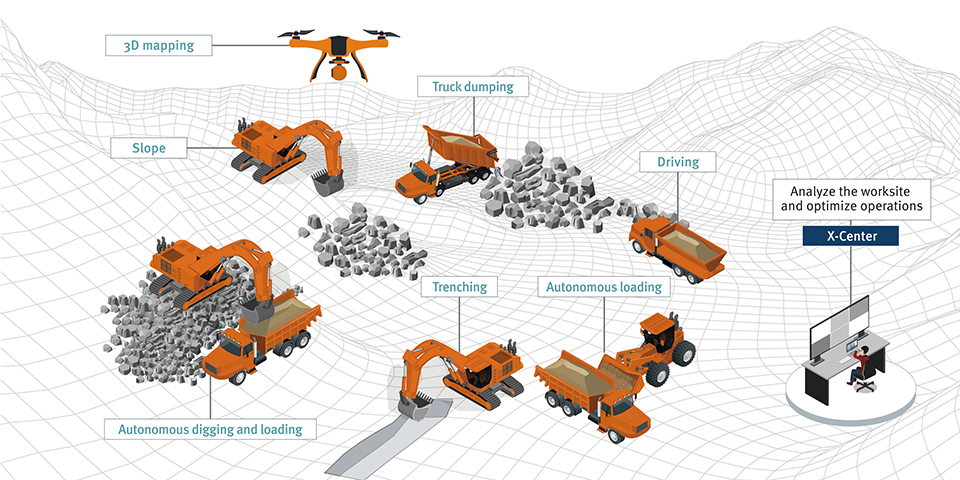

Concept-X is a solution-based on technology optimized for future construction sites, such as automated construction site surveying tasks using drones, unmanned automation of equipment, and remote control-based on 5G communication. Concept-X will satisfy customer needs and create new added value by increasing productivity and reducing costs and risks based on projects completed accurately and efficiently at the construction site.

X-center

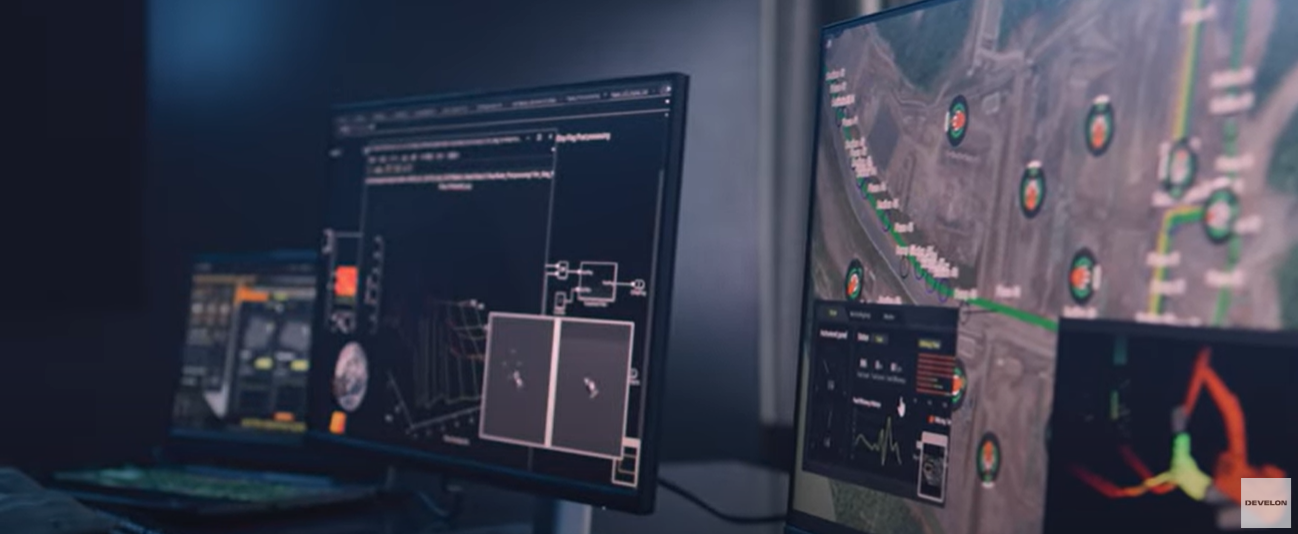

As the core of Concept-X, X-Center is a control system that enables the user to view equipment at the construction site and worksite at a glance. The terrain of the worksite is surveyed through scanning using drones, and the terrain data obtained by the survey is created in 3D form to be used in establishing work plans. The data collected from various sites are analyzed to instruct unmanned equipment and manage the equipment in an integrated manner. In addition, Fleet Manager of X-Center enables the user to monitor and diagnose remotely machine data for efficient job management and support, such as earthwork status, driving route and work area planning, equipment location and operation status, major parts status, and abnormal signal detection.

Autonomous Solution

Equipment with an unmanned, automated solution can perform work accurately and efficiently by receiving the analyzed data from X-Center. The working movement of unmanned equipment is most efficiently created using the actual data from experienced operators to realize maximum productivity.

The unmanned excavator implemented by HD CONSTRUCTION EQUIPMENT has a recognition, estimation, and control system. The unmanned excavator recognizes the surrounding environment using various sensors installed on the excavator, estimating and carrying out local work sequence plans and operation trajectory, and driving routes autonomously. In addition, the unmanned excavator performs work safely and accurately based on the control system that prevents collision and roll-over. Basically, the unmanned wheel loader has the same system as the unmanned excavator. Note, however, that more technical efforts are reflected in determining the optimal route and securing driving safety because the wheel loader runs more frequently than the excavator. Besides, the unmanned wheel loader establishes and implements optimal work plans autonomously through remote equipment control and transmission of equipment operation status and workload information.

Prognostics and Health Management (PHM)

Unexpected equipment failure means significant economic losses and risks in the future construction site where fleet management (integrated management of many equipment groups) will become commonplace. PHM is the technology that allows our future equipment to diagnose their own condition and alert users of possible failure in advance, so that work can be performed without setbacks in any operating environment. PHM-implemented unmanned equipment can monitor their own health status comprehensively by detecting and analyzing the stress of major parts and functions through the self-diagnosis function and monitoring performed in real time. PHM manages risk factors in advance by forecasting the remaining life through the checking of the status change history of each part as well as the overall status at the time.

“Concept-X”: an innovative solution for the future construction site

HD CONSTRUCTION EQUIPMENT will contribute to customer convenience with differentiated competitiveness by preemptively implementing the worksite business model with maximized efficiency and productivity. This is accomplished through work orders based on accurate survey and data; unmanned equipment that recognizes, plans, and works autonomously and equipment health management based on prognostics beginning with “Concept-X,” a solution optimized for the future construction site.

Inquiry

Need help finding more

information about our equipment?

Find a Dealer

Need help finding a dealer

near you?

New 7M Series

Need help finding more information about our equipment?

Need help finding a dealer near you?